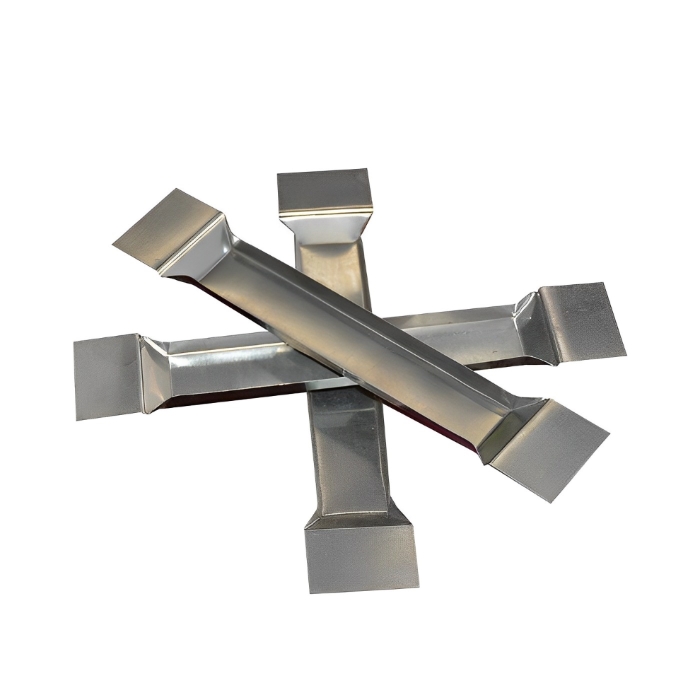

Customized Tungsten Boats For The Vacuum Coating

Type and Size

|

content |

size (mm) |

Slot length (mm) |

Slot Depth(mm) |

|

tungsten boat |

0.2*10*100 |

50 |

2 |

|

0.2*15*100 |

50 |

7 |

|

|

0.2*25*118 |

80 |

10 |

|

|

0.3*10*100 |

50 |

2 |

|

|

0.3*12*100 |

50 |

2 |

|

|

0.3*15*100 |

50 |

7 |

|

|

0.3*18*120 |

70 |

3 |

|

| Note: Special sizes can be customized according to customer requirements | |||

Features

Tungsten boat is used for vacuum evaporator of granular materials. Tungsten boats can also be used to evaporate thin, short wires or wet wires. Tungsten evaporation boat is suitable for experiment or modeling work in small evaporation system, like bell jar. As a special and effective boat-shaped container, tungsten boat is widely used in electron ray spraying, sintering and annealing in vacuum coating.

Tungsten evaporation boat is manufactured on special production line; our company can provide customers with high quality products. We guarantee the tungsten raw materials we use are high-purity. Advanced technology and special treatment methods are applied in the surface treatment of our products. Our company can produce tungsten boat for vacuum evaporation according to customer's drawings.

Applications

Tungsten boat can be applied in light industry, electronic industry, military industry, semiconductor industry: coating, sintering precision ceramics, capacitor sintering, bell jar, electron beam spraying. X-ray diagnostic target, crucible, heating element, X-ray radiation shield, sputtering target, electrode, semiconductor base plate, and electron tube component, emission cathode of electron beam evaporation, and cathode and anode of ion implanter.