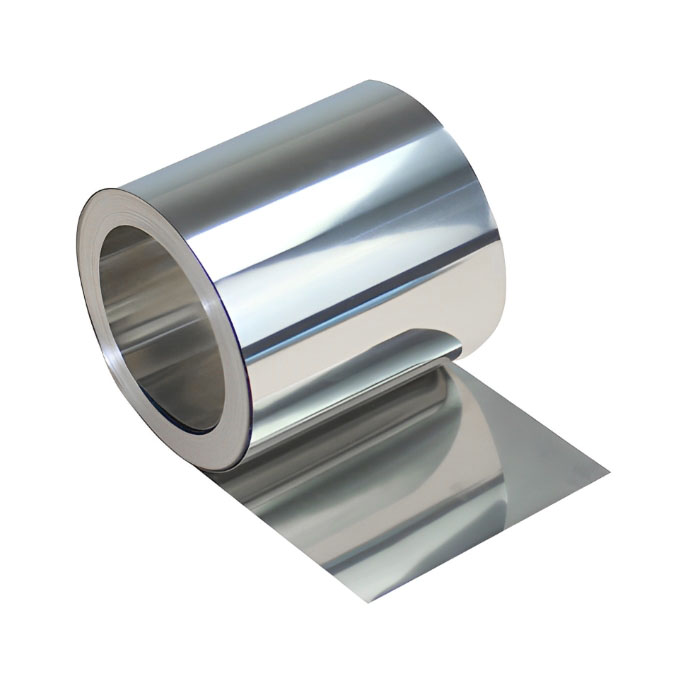

Molybdenum Sheet

-

Molybdenum Foil, Molybdenum Strip

Molybdenum plates are formed by rolling the pressed and sintered molybdenum plates. Usually, 2-30mm-thick molybdenum is called molybdenum plate; 0.2-2mm-thick molybdenum is called molybdenum sheet; 0.2mm-thick molybdenum is called molybdenum foil. Molybdenum plates with different thicknesses need to be manufactured by rolling machines with different models. The thinner molybdenum sheets and molybdenum foils have the better crimp property. When manufactured by a continuous rolling machine with tensile force and supplied in coils, molybdenum sheets and foils are called molybdenum strips.

Our company can carry out vacuum annealing treatment and leveling treatment on molybdenum plates. All the plates are subjected to cross rolling; moreover, we pay attention to the control over the grain size in the rolling process. Therefore, the plates have extremely good bending and stamping properties.

-

Thin Molybdenum Strip Wear Resistance

The company has more than 15 sets of rolling machines with different specifications, which can provide customers with various square, round,or strip tungsten-molybdenum foil, sheet, and plate, and can vacuum anneal the molybdenum strip. Our molybdenum strips and other rolled products have excellent physical properties and are widely used in the vacuum furnace industry to make tungsten-molybdenum heat insulation screens, tungsten-molybdenum heat generators, furnace support frames and containers,the coating industry to make tungsten boats, molybdenum boats and cathodes, and the electronics industry to make tungsten targets, molybdenum targets and various tungsten-molybdenum deep processing products.

-

Molybdenum Plate & Pure Molybdenum Sheet

Chemical cleaned molybdenum sheets are with metallic silver luster. They’re .rolled and annealed to reach the optimum condition for the desired end use. We can provide molybdenum sheets with different widths, thicknesses, surface conditions as well as impurity conditions upon the customers’ requirements.

-

Molybdenum Heat Shield&Pure Mo screen

Molybdenum heat shielding parts with high density, exact dimensions, smooth surface, convenient-assembly and reasonable-design has great significance in improving the crystal-pulling. As the heat-shield parts in the sapphire growth furnace, the most decisive function of molybdenum heat shield (molybdenum reflection shield) is to prevent and reflect the heat. Molybdenum heat shields can also be used in other prevent heat needs occasions.

-

Polished Molybdenum Disc& Molybdenum Square

Molybdenum is gray-metallic and has the third-highest melting point of any element next to tungsten and tantalum. It is found in various oxidation states in minerals but does not exist naturally as a free metal. Molybdenum allows readily to form hard and stable carbides. For this reason, Molybdenum is frequently used for making steel alloys, high strength alloys, and superalloys. Molybdenum compounds usually have a low solubility in water. Industrially, they are used in high-pressure and high-temperature applications such as pigments and catalysts.