Molybdenum

-

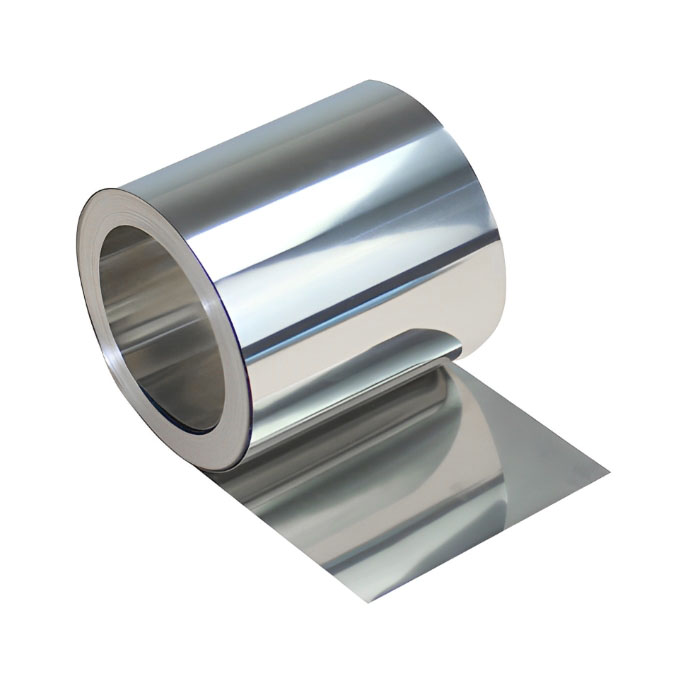

Molybdenum Foil, Molybdenum Strip

Molybdenum plates are formed by rolling the pressed and sintered molybdenum plates. Usually, 2-30mm-thick molybdenum is called molybdenum plate; 0.2-2mm-thick molybdenum is called molybdenum sheet; 0.2mm-thick molybdenum is called molybdenum foil. Molybdenum plates with different thicknesses need to be manufactured by rolling machines with different models. The thinner molybdenum sheets and molybdenum foils have the better crimp property. When manufactured by a continuous rolling machine with tensile force and supplied in coils, molybdenum sheets and foils are called molybdenum strips.

Our company can carry out vacuum annealing treatment and leveling treatment on molybdenum plates. All the plates are subjected to cross rolling; moreover, we pay attention to the control over the grain size in the rolling process. Therefore, the plates have extremely good bending and stamping properties.

-

Molybdenum Seed Holder for Single Crystal Silicone CZ Crystal Growers Furnace Parts

Polished 99.95% Purity Molybdenum Seed Holder Apply In Hot Zone Of Sapphire Growth

Widely used in growing artificial crystal for its good properties in high temperature.

We have our own raw materials and processing plant, we can offer best quality products with best price

-

Custom Machined Special-shape Fabricated Molybdenum Parts

Custom machined special-shape fabricated processing molybdenum parts for furnace

Molybdenum is a refractory metal that is very useful in many industrial processes and applications that would not be possible with many of the more common metals and alloys. Refractory metals and alloys are extraordinarily resistant to heat and have unique physical properties.

-

High Purity 99.95% Molybdenum Cups Stamping Molybdenum Cups

Stamping Cups &Disc for PDC&PCBN cutter

Cups &Discs are used in polycrystalline diamond compact bit. (PDC)

Size of Cups &Disc according to your requirement.

Cups can be offered with molybdenum, ziconium, tantalum, niobium,titanium, cobalt material.

Cup Forms include cambered cups, conical cups, convex spherical cup, cuneate cup, trapezoid cup, etc.

Cup can be offered with different sizes. Popular size as follows, 0808 1004 1008 1204 1208 1210 1304 1308 1313 1316 1504 1604 1608 1613 1904 1908 1913 0804 etc … -

Molybdenum Riveted Boat,Molybdenum Tray

Molybdenum riveted boats are formed from processed molybdenum plates that have undergone cutting, folding, riveting, welding. For customer convenience, these molybdenum boats can be shaped to various specifications including square, rectangular, round, trapezoidal, etc.

Molybdenum boats and Molybdenum Trays are great for evaporation materials because molybdenum can withstand low and high temperatures, which other elements cannot, without being affected. This also makes them highly effective in carrying boats in furnace machines. Additionally, Molybdenum boats are used in the rare earth industry, nuclear fuel sintering, and capacitor discharged sintering.

We can provide various molybdenum boats, molybdenum trays, and molybdenum wires with the shortest lead time and the best price.

-

Molybdenum Electrodes Bars For Glass Melting Electrodes

Process of glass molybdenum electrode: isotactic pressing – sintering with medium frequency furnace – forging to various shapes – turning, rolling, planning and milling to finished parts. We can also offer different kinds of moly electrodes as your requirements.

We have produced molybdenum electrode for years, and spare no effort to the improvement of the electrodes performance. With the excellent characteristics of high strength, resistant to oxidation under high temperature, long life, good corrosion resistance, these high pure moly electrodes are widely used in many fields such as daily-use glass, optical glass, insulation material and glass fiber, and received good reputes. -

Thin Molybdenum Strip Wear Resistance

The company has more than 15 sets of rolling machines with different specifications, which can provide customers with various square, round,or strip tungsten-molybdenum foil, sheet, and plate, and can vacuum anneal the molybdenum strip. Our molybdenum strips and other rolled products have excellent physical properties and are widely used in the vacuum furnace industry to make tungsten-molybdenum heat insulation screens, tungsten-molybdenum heat generators, furnace support frames and containers,the coating industry to make tungsten boats, molybdenum boats and cathodes, and the electronics industry to make tungsten targets, molybdenum targets and various tungsten-molybdenum deep processing products.

-

Customer Specific Pure Molybdenum Rings for Synthetic Diamonds

This product uses high-quality molybdenum powder Mo-1. Molybdenum ring is mainly used in aerospace, rare earth smelting, electric light, chemical equipment, medical equipment, metallurgical machinery, smelting equipment, petroleum, and other fields.

molybdenum ring has a high density, high purity, good dimensional accuracy.

-

Pure Molybdenum Thermal Spray Wire for Galling and Scuffing Resistance

Molybdenum wire is mainly refers to the wire cutting in the condition of high voltage electric field made from molybdenum and other precious metals. It used in wire cutting machine tool.

-

Molybdenum Tube,Molybdenum Pipe

Molybdenum tube produced by Zhaolixin are formed by machining blanks manufactured by our factory, which can ensure high-temperature resistance and mechanical strength of materials. Zhaolixin has in-depth understanding on the processing of tungsten-molybdenum materials and is guaranteed by exquisite CNC equipment, so the molybdenum tube produced by Zhaolixin can meet the requirements of customers on the tolerance of concentricity and equal size, and molybdenum tube with larger differences of diameter-height ratio can be manufactured.

-

Pure Molybdenum Rod, Molybdenum Bar, Molybdenum Electrode

Molybdenum rods have theproperties of high melting point, good thermal conductivity and low thermal expansion. At high temperature, they can resist oxidation and have high strength without any distortion during the procession, etc.

Molybdenum rods are manufactured as random length pieces or cut to customers’ desired lengths.In addition, there are three different surface processes or finishes which are provided, depending on the desired end use of the molybdenum rods.

-

Ground Molybdenum Crucible for Vacuum Coating

Crucibles produced by Zhaolixin Tungsten & Molybdenum Co., Ltd. include small tungsten crucibles and molybdenum crucibles by forging,plate spinning tungsten and molybdenum crucibles, vacuum welding tungsten crucibles and molybdenum crucibles, large sintering tungsten crucibles and molybdenum crucibles as well as sintering tungsten-molybdenum alloy crucibles.

Bar turned crucibles are formed by turning high-quality bars of our company, and feature high density, no crack and sand hole inside, bright surfaces, uniform color and luster as well as accurate dimensions.