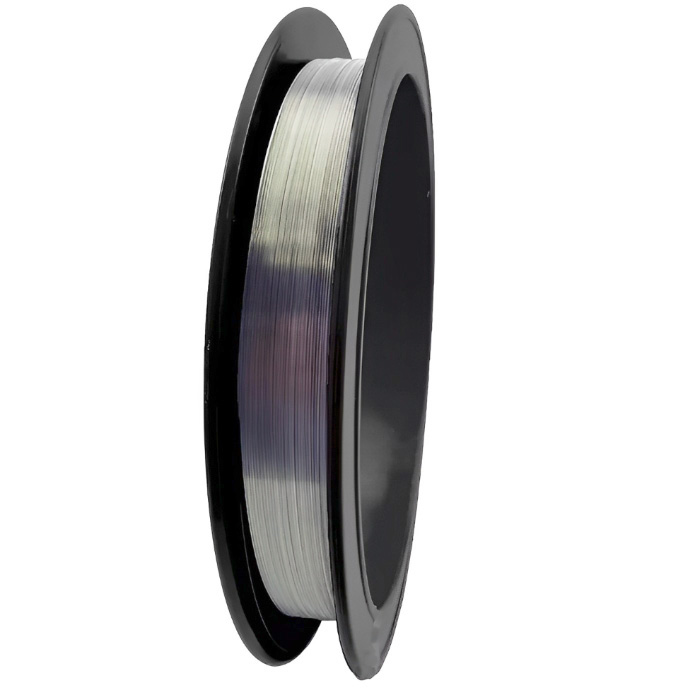

High Quality Purity 99.95% Tungsten Wire

Type and Size

W-wire is regular black covered with graphite. After graphite is removed it is metallic luster.

|

Designation |

Tungsten Content |

Impurity Elements Content |

|

|

Total |

Each |

||

|

WAL1, WAL2 |

≥99.95% |

≤0.05% |

≤0.01% |

|

W1 |

≥99.95% |

≤0.05% |

≤0.01% |

|

W2 |

≥99.92% |

≤0.08% |

≤0.01% |

|

Note: Potassium is not counted in impurities content. |

|||

Diameter tolerance(%):

|

Diameter (μm) |

Weight (mg/200mm) |

Weight(mg/200mm) Tolerance(%) |

Diameter Tolerance(%) |

||||

|

Grade 0 |

Grade 1 |

Grade 2 |

Grade 0 |

Grade 1 |

Grade 2 |

||

|

5≤d≤12 |

0.075~0.44 |

- |

±4 |

±5 |

- |

- |

- |

|

12<d≤18 |

>0.44~0.98 |

- |

±3 |

±4 |

- |

- |

- |

|

18<d≤40 |

>0.98~4.85 |

±2 |

±2.5 |

±3 |

- |

- |

- |

|

40<d≤80 |

>4.85~19.39 |

±1.5 |

±2.0 |

±2.5 |

- |

- |

- |

|

80<d≤300 |

>19.39~272.71 |

±1.0 |

±1.5 |

±2.0 |

- |

- |

- |

|

300<d≤350 |

>272.71~371.79 |

- |

±1.0 |

±1.5 |

- |

- |

- |

|

350<d≤500 |

- |

- |

±1.5 |

±2.0 |

±2.5 |

||

|

500<d≤1800 |

- |

- |

±1.0 |

±1.5 |

±2.0 |

||

Technical process:

Tungsten Powder → Isostatic Pressing → Bar Billet →Sintering → Semi-finished bar →Forging→ Swaging → Drawbench → End products → Inspection → Packing

Features

1.High melting point and high corrosion resistance

2. Super thermal efficiency

3. 99.95% Purity

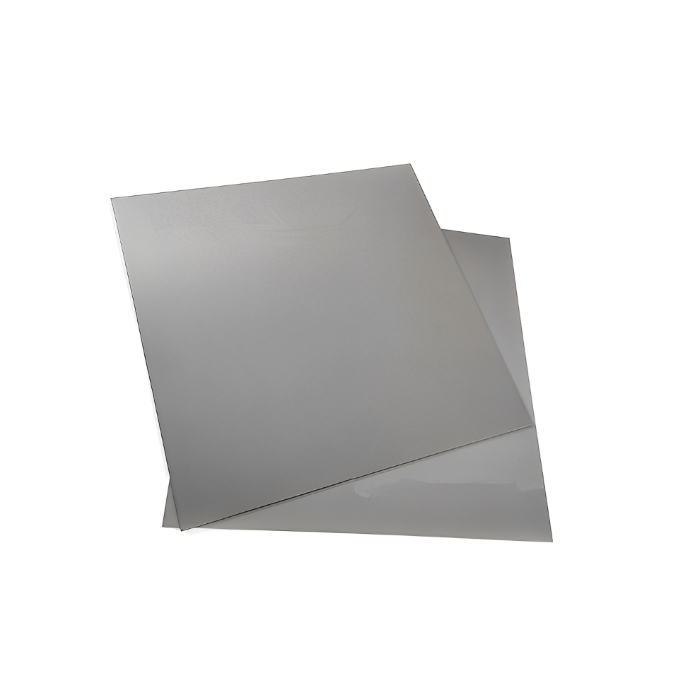

4. Appearance: silver white/gray metallic luster The surface of electrolytic polished tungsten wire shall be smooth, clean, gray silver with metal luster. The tungsten wire features excellent formability, short life and supper lighting efficiency.

Applications

1. Producing electric light source parts and electric vaccum components;

2. Producing heating elements and refractory parts in high temperature furnaces;

3. Producing heating elements used in vaccum metalizing or plating.