Pure Tungsten Tube&Tungsten Pipe

Type and Size

|

Regular Size of Our Regular Tungsten Tube |

|||||||

| Material | Shape | OD inch | OD mm | ID inch | ID mm | Length inch | Length mm |

| W | tungsten tube | 0.28" | 7.112 mm | 0.16" | 4.064 mm | 4" | 101.6 mm |

| W | tungsten tube | 0.35" | 8.89 mm | 0.2" | 5.08 mm | 20" | 508 mm |

| W | tungsten tube | 0.48" | 12.192 mm | 0.32" | 8.128 mm | 32" | 812.8 mm |

| W | tungsten tube | 2" | 50.8 mm | 1.58" | 40.132 mm | 32" | 812.8 mm |

| W | tungsten tube | 5.8" | 147.32 mm | 4.9" | 124.46 mm | 40" | 1016 mm |

| We can produce the tungsten tubes according to your requirement. | |||||||

|

Chemical Composition of Pure Tungsten Tube |

|

| Element | % maximum |

| C | 0.01 max |

| O | 0.01 max |

| N | 0.01 max |

| Fe | 0.01 max |

| Ni | 0.01 max |

| Si | 0.01 max |

Features

|

Material |

Pure tungsten |

|

Specification |

(OD3~200)×ID(2~180)×L(100~1500)mm |

|

Density |

19.3g/cm3 |

|

Purity |

99.95% |

|

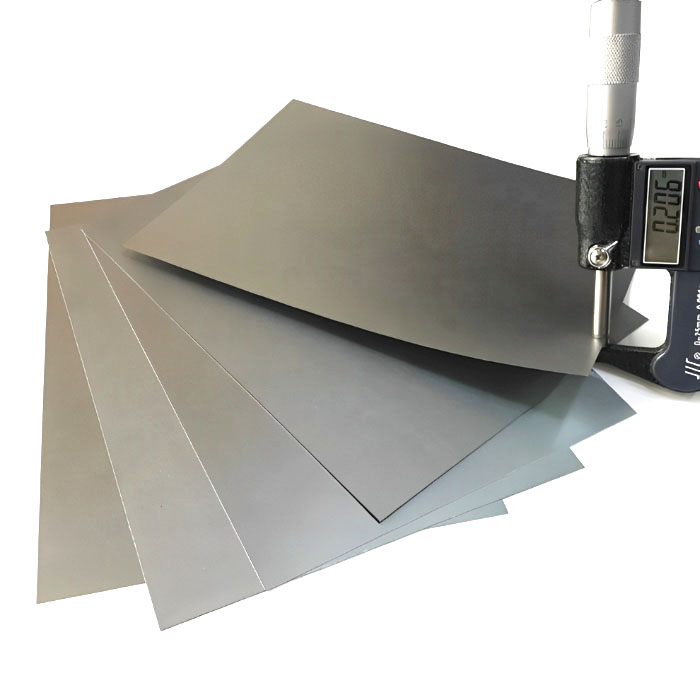

Surface |

Black, ground |

|

Grade |

W-1 |

Applications

Because of tungsten’s high melting point of 3400 ℃, sintered tungsten tube is widely used in industrial furnaces such as sapphire growth furnace, quartz glass furnace and rare earth smelting furnace. Due to its high utilization rate, tungsten tube is more and more widely used in solar energy, photoelectric industry and quartz glass melting field. We can produce sintered tungsten tubes in the diameters not exceeding 500mm and lengths not exceeding 1500mm. We can provide high-precision tungsten tubes with smooth surface, excellent straightness and high temperature creep resistance.