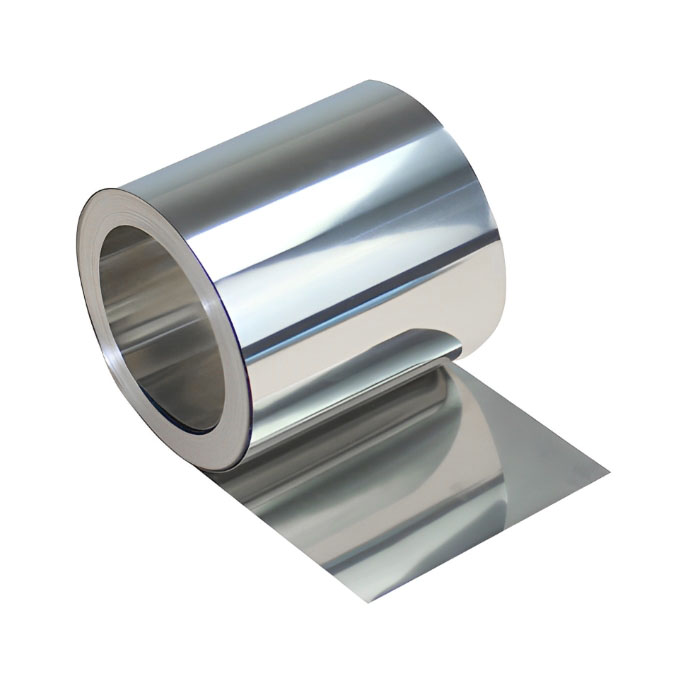

Molybdenum Foil, Molybdenum Strip

Specifications

In the rolling process, slight oxidation of surfaces of molybdenum plates can be removed in an alkaline cleaning mode. Alkaline cleaned or polished molybdenum plates can be supplied as relatively thick molybdenum plates according to customer requirements. With better surface roughness, molybdenum sheets and foils do no need polishing in the supplying process, and can be subjected to electrochemical polishing for special needs. Achemetal can machine molybdenum plates, and can supply goods in the forms of round and square molybdenum.

Type and Size:

|

Thickness(mm) |

Width(mm) |

Length(mm) |

|

0.05 ~ 0.10 |

150 |

L |

|

0.10 ~ 0.15 |

300 |

1000 |

|

0.15 ~ 0.20 |

400 |

1500 |

|

0.20 ~ 0.30 |

650 |

2540 |

|

0.30 ~ 0.50 |

750 |

3000 |

|

0.50 ~ 1.0 |

750 |

5000 |

|

1.0 ~ 2.0 |

600 |

5000 |

|

2.0 ~ 3.0 |

600 |

3000 |

|

> 3.0 |

600 |

L |

Chemical Composition:

| Mo Content | Total Content of Other Elements | Each Element Content |

| ≥99.95% | ≤0.05% | ≤0.01% |

Features

1. The purity of pure molybdenum sheet is over 99.95%. While the purity of high-temperature rare-earth element added molybdenum sheet is above 99%;

2. The density of molybdenum sheet is more than or equals to 10.1g/cm3;

3. The flatness is less than 3%;

4. It has good performances of high strength, uniform internal organization and good resistance to high temperature creep;

Applications

- For producing electric light source parts, components of electric vacuum and electric power semiconductor.

- For producing Mo-boats, heat shield and heat bodies in high temperature furnace.

- Used to produce Sputtering Targets.