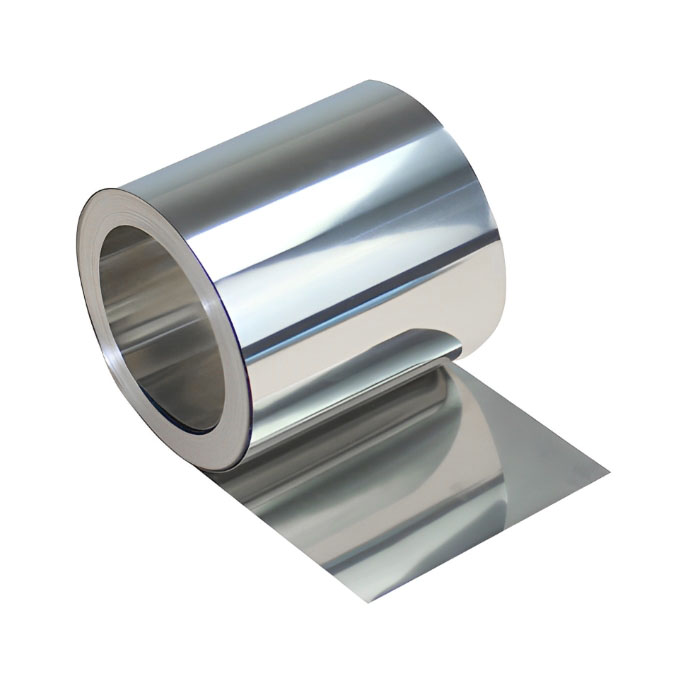

Custom Machined Special-shape Fabricated Molybdenum Parts

Description

Custom machined special-shape fabricated processing molybdenum parts for furnace

Molybdenum is a refractory metal that is very useful in many industrial processes and applications that would not be possible with many of the more common metals and alloys. Refractory metals and alloys are extraordinarily resistant to heat and have unique physical properties.

Features

1. Molybdenum content≥99.95%, melting point: 2610℃.

2.High temperature resistant, high tensile strength

3. Outstanding thermal conductivity, low thermal expansion coefficient

4. low vapor pressure and wear resistance

5. Strong anti-oxidation, anticorrosion

Applications

Molybdenum parts are widely used for petrochemical, aerospace, automotive industry, sapphire growing, glass and ceramics, furnace construction and heat treating, electric light source, electro vacuum, power industry, rare earth metal industry, quartz industry, ion implantation, LED industry, solar energy, heat sinks and electronic packaging materials and so on.

Furnace components

Many high temperature industrial furnaces use molybdenum (moly) components for such things as elements, element supports, power terminators, and process fixtures

Hot isostatic press (HIP) construction relies on inner shells fabricated from molybdenum sheets

These are used to contain the workload and support the heating elements

Likewise, flat heating elements made from moly sheet are used in vacuum and hydrogen furnaces

Heat shielding and other furnace structures help round out the use of moly in the furnace industry

Electronic and semiconductor components

Silicon wafer processing relies on the use of ion implantation systems which inject ions at high energy directly into silicon wafer surfaces

The ion plasma source is energized via tungsten electrodes which operate within fabricated tungsten arc chamber