News

-

Applications of Tungsten and Molybdenum Materials

Tungsten-molybdenum and their alloys are important materials for electronic and power equipment manufacturing, metal material processing, glass manufacturing, high-temperature furnace structural parts manufacturing, aerospace and national defense industry applications due to their good thermal an...Read more -

Characteristics of Tungsten and Molybdenum Materials

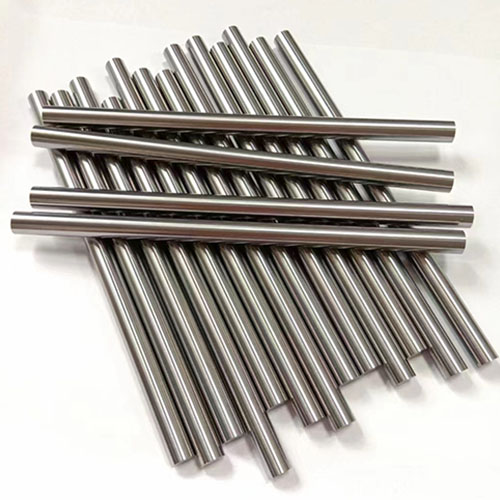

W: Tungsten, chemical symbol W, atomic number 74, atomic mass 183.85, density 19.3 g/cm3. After smelting, tungsten is a silver-white glossy metal with a very high melting point, a great hardness, anti-friction and corrosion resistance, high thermal conductivity, low coefficient of thermal expansi...Read more -

High Specific Gravity Tungsten Alloy Dumbbells Made of Tungsten-Nickel-Iron Alloy

Tungsten-nickel-iron alloy is the main material for manufacturing high-density tungsten alloy dumbbells. It is made of tungsten, nickel, and iron powders by mixing, pressing and sintering, and has certain material advantages. Among them, the content of tungsten is the largest, reaching 80% to 90%...Read more -

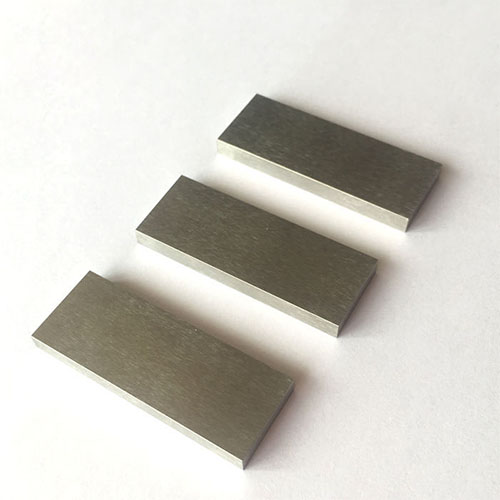

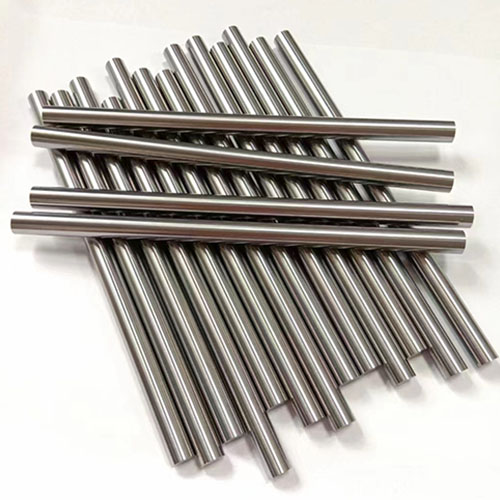

TZM Alloy

The common preparation methods of TZM alloy (molybdenum zirconium titanium alloy) are: arc melting-casting method and powder metallurgy technology. TZM alloy rod arc melting-casting method is to use electric arc to melt pure molybdenum and add a certain amount of alloying elements such as Ti and ...Read more -

A material with special talents-Tungsten

You can find tungsten at work whenever the heat’s on. Because no other metal can compare with tungsten when it comes to heat resistance. Tungsten has the highest melting point of all metals and is therefore also suitable for very high-temperature applications. It is also characterized by a ...Read more -

Precautions for the use of tungsten and molybdenum products

1. Storage Tungsten and molybdenum products are easy to oxidize and change color, so they must be stored in an environment with a humidity below 60%, a temperature below 28°C, and isolated from other chemicals. The oxides of tungsten and molybdenum products are soluble in water and are acidic, pl...Read more -

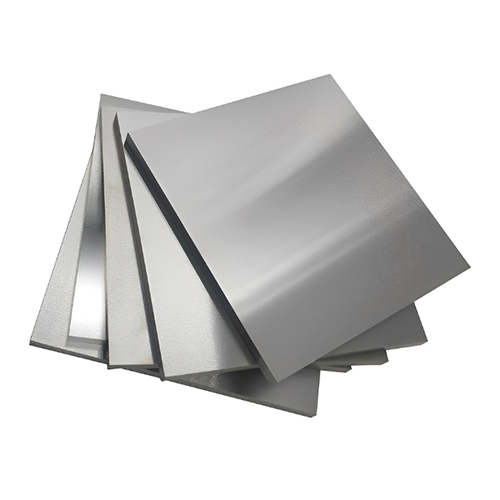

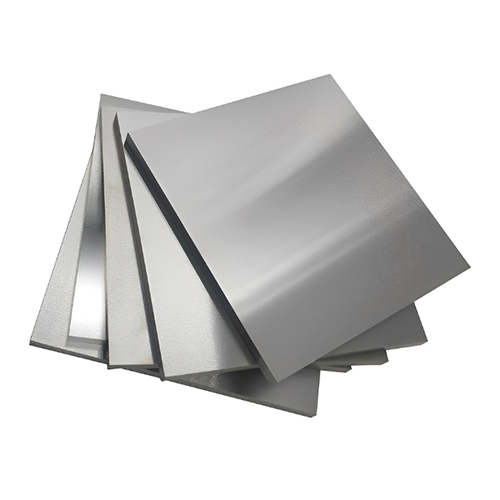

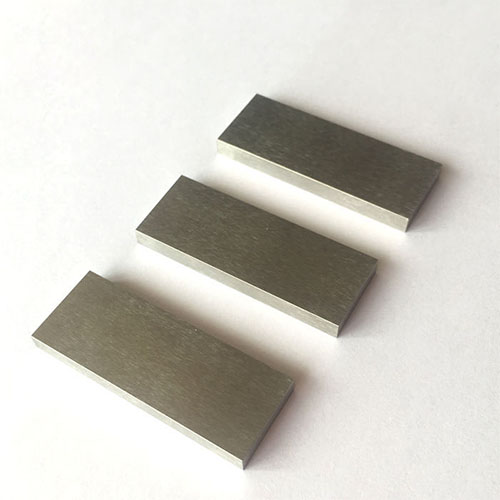

Production technology of tungsten plate

Powder metallurgy tungsten usually has a fine grain, its blank is generally selected by high temperature forging and rolling method, the temperature is generally controlled between 1500~1600℃. After the blank, the tungsten can be further rolled, forged or spun. The press...Read more -

The use of Molybdenum wire, Molybdenum powder, and MoO3

MoO3 Uses: Mainly used in powder metallurgy to prepare molybdenum powder, make catalysts, steel additives and pigments. Molybdenum powder Product description: This product is gray metal powder, which will gradually oxidize in the air, and is prepared by reducing molybdenum trioxide with hydrogen....Read more