High Quality Molybdenum Mandrel for Piercing Seamless Tube

Description

High density molybdenum piercing mandrels

Molybdenum Piercing Mandrels are used for piercing seamless tubes of stainless, alloy steel and high-temperature alloy, etc

Density >9.8g/cm3 ( molybdenum alloy one, density>9.3g/cm3)

Type and Size

Table 1

|

Elements |

Content (%) | |

|

Mo |

( See Note ) | |

|

Ti |

1.0 ˜ 2.0 | |

|

Zr |

0.1 ˜ 2.0 | |

|

C |

0.1 ˜ 0.5 | |

|

Chemical elements / not more than |

Fe | 0.0060 |

| Ni | 0.0030 | |

| Al | 0.0020 | |

| Si | 0.0030 | |

| Ca | 0.0020 | |

| Mg | 0.0020 | |

| P | 0.0010 | |

Table 2

|

Diameter |

Tolerance of diameter |

Length |

Tolerance of length |

Semifinished type |

|

20-40mm |

0 to +2mm |

60-80mm |

0 to +3mm |

A type |

|

45-55mm |

0 to +2mm |

80-110mm |

0 to +3mm |

A type |

|

60-80mm |

0 to +3mm |

160-200mm |

0 to +4mm |

B type |

|

85-100mm |

0 to +4mm |

180-260mm |

0 to +5mm |

B type |

|

110-150mm |

0 to +5mm |

200-300mm |

0 to +6mm |

B type |

|

160-250mm |

0 to +6mm |

280-350mm |

0 to +8mm |

B type |

Tips:Product diameter specification: Φ 20-300 mm, and can be specially processed according to the drawing requirements.

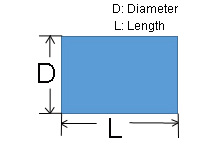

Type A:

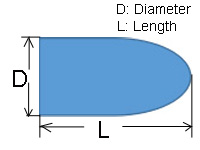

Type B:

Applications

Mainly used for perforating seamless steel tubes such as stainless steel, brazed steel, bearing steel and high temperature alloy steel.

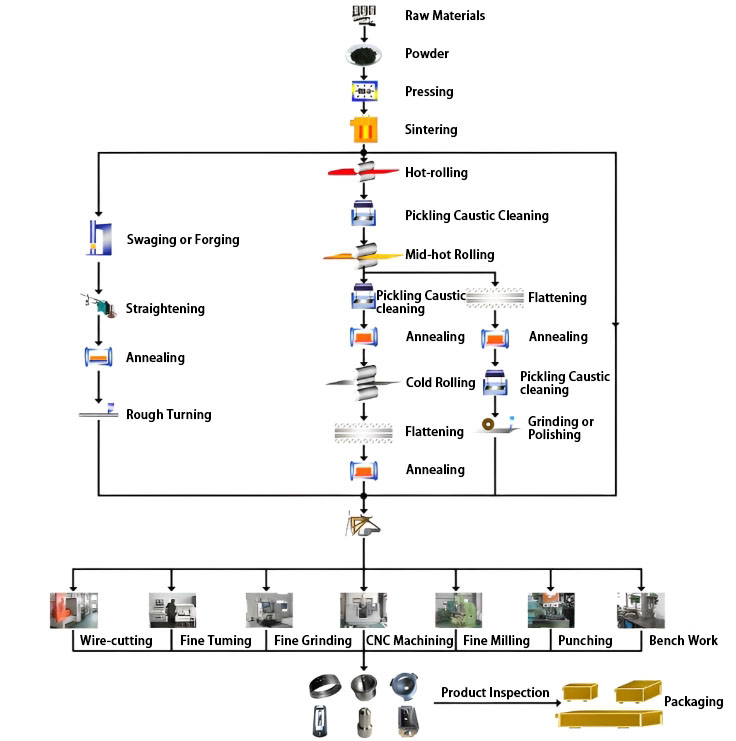

Craftsmanship

Raw Material: Starting from raw materials, we select high-quality raw materials, which is very prominent in the stability and consistency of products. Identify different brands of raw materials and mark the batch number. And each batch of raw materials shall be sampled, inspected and archived. Ensure the traceability of each finished product and continuously improve the product quality.

Powder: The control of the milling process of Zhaolinxin Metal products is very accurate, with several large mixers and vibration platforms to ensure that the materials in the pulverizing and mixing process can be fully stirred and evenly distributed, so as to ensure the internal organization consistency of the products.

Pressing: In the process of powder compacting, the powder is pressed by isostatic pressing equipment to make its internal structure uniform and dense. Zhaolixin has very perfect batch mold, and also has isostatic pressing equipment to meet the production of ultra-large batches of products.

Sintering: In powder metallurgy, after the metal powder is formed by isostatic pressing, it is heated at a temperature lower than the melting point of the main components to make the particles connect, so as to improve the performance of the products, which is called sintering. After the powder is formed, the dense body obtained by sintering is a kind of polycrystalline material. The sintering process directly affects the grain size, pore size and grain boundary shape and distribution in the microstructure, which is the core process of powder metallurgy.

Forging: The forging process can make the material obtain higher density, better mechanical properties, and play a role in strengthening the surface. Accurate control of the processing rate and forging temperature of tungsten and molybdenum materials is an important factor for the superior performance of Zhaolixin tungsten and molybdenum materials. A processing method of using a forging machine to apply pressure to a metal blank to plastically deform it to obtain a forging with certain mechanical properties, certain shape and size.

Rolling: The rolling process makes the metal material produce continuous plastic deformation under the pressure of the rotating roll, and obtain the required section shape and properties. With advanced tungsten and molybdenum cold and hot rolling technology and equipment, from tungsten and molybdenum metal blank to the production of tungsten and molybdenum foil, Zhaolixinguarantees you more advanced production technology and superior metal properties.

Heat-Treat: After the forging and rolling process, the material is subjected to the heat treatment process to completely eliminate the internal structural stress of the material, give play to the material performance, and make the material easier for subsequent machining. Zhaolixin has dozens of vacuum furnaces and heat treatment hydrogen furnaces to meet the rapid delivery of mass production orders.

Machining: The material of Zhaolixin has undergone complete heat treatment, and then processed into various customized sizes by machining equipment such as turning, milling, cutting, grinding, etc., and ensures that the internal organization of tungsten and molybdenum materials is tight, stress-free and hole-free, which can meet the needs of customers.

Quality Assurance: Quality inspection and control will be carried out from raw materialsand for each steps of the production , so as to continuously ensure the quality every product. At the same time, when finished products are delivered from the warehouse, the appearance, size and internal organization of materials are tested one by one. Therefore, the stability and consistency of products are especially prominent.