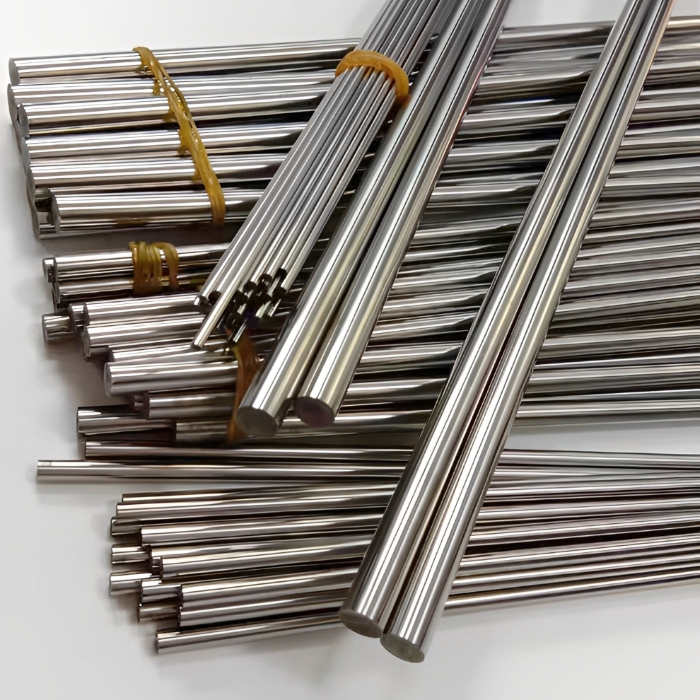

High Temperature Molybdenum Lanthanum (MoLa) Alloy Rod

Type and Size

- Material: Molybdenum Lanthanum Alloy, La2O3: 0.3~0.7%

- Dimensions: diameter (4.0mm-100mm) x length (<2000mm)

- Process: Drawing, swaging

- Surface: Black, chemically cleaned, Grinding

Features

1. The density of our molybdenum lanthanum rods is from 9.8g/cm3 to 10.1g/cm3; The smaller diameter,the higher density.

2. Molybdenum lanthanum rod possesses features with high hot hardness, high thermal conductivity, and low thermal expansion to hot work steels

3. It is a silvery-white, hard, transition metal, which has the eighth-highest melting point of any element;

4. It has the lowest heating expansion of any commercially used metal.

Applications

- Used in illumination, electric vacuum device.

- Used for tube component element in cathode-ray pipe, power semiconductor device.

- Used to produce tools for manufacturing glass and glass fiber.

- Used to produce internal part in light bulbs, high temperature heat shield, annealing Filament and Electrode, high temperature container and component in microwave magnetron.

Molybdenum lanthanum rods are widely applied for heating elements in high temperature furnaces, electrodes, screws, rabbles in rare earth smelting industry, heating electrodes in glass industry and support of lamp in the lighting industry, etc.

Write your message here and send it to us