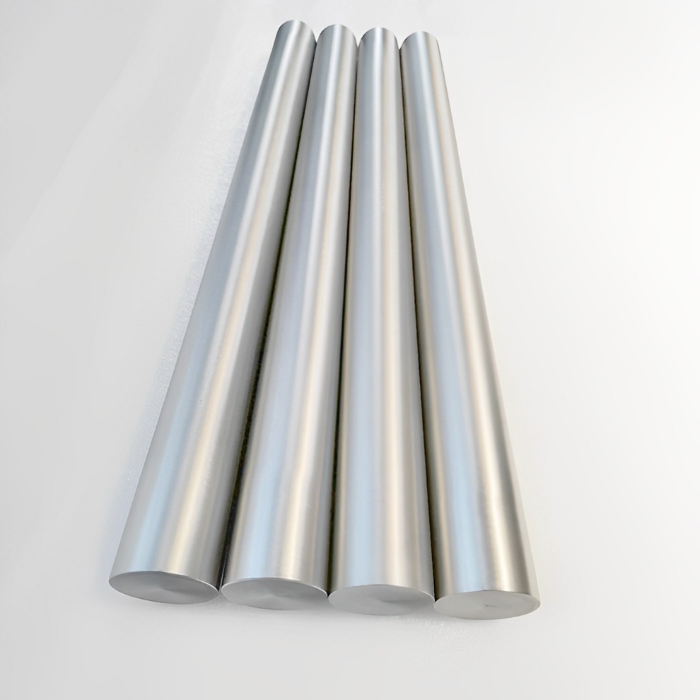

High Quality TZM Molybdenum Alloy Rod

Type and Size

TZM Alloy rod can also be named as: TZM molybdenum alloy rod, titanium-zirconium-molybdenum alloy rod.

| Item Name | TZM Alloy Rod |

| Material | TZM Molybdenum |

| Specification | ASTM B387, TYPE 364 |

| Size | 4.0mm-100mm diameter x <2000mm L |

| Process | Drawing, swaging |

| Surface | Black oxide, chemically cleaned, Finish turning, Grinding |

We can also provide machined TZM Alloy parts per drawings.

Chemical Composition of TZM

Main Components: Ti: 0.4-0.55%, Zr: 0.06-0.12%, C: 0.01-0.04%

|

Others |

O |

Al |

Fe |

Mg |

Ni |

Si |

N |

Mo |

|

Content (wt, %) |

≤0.03 |

≤0.01 |

≤0.002 |

≤0.002 |

≤0.002 |

≤0.002 |

≤0.002 |

Bal. |

Advantages of TZM compared to pure molybdenum

- Above 1100°C tensile strength is about twice that of unalloyed molybdenum

- Better creep resistance

- Higher recrystallization temperature

- Better welding properties.

Features

- Density: ≥10.05g/cm3.

- Tensile strength: ≥735MPa.

- Yield strength: ≥685MPa.

- Elongation: ≥10%.

- Hardness: HV240-280.

Applications

TZM costs approximately 25% more than pure molybdenum and costs only about 5-10% more to the machine. For high strength applications such as rocket nozzles, structural furnace components, and forging dies, it can be well worth the cost differential.

Write your message here and send it to us